New Energy Power Battery

There are many types of new energy power batteries, which can be divided into chemical, physical and biological batteries according to the type. From a structural point of view, it can be divided into two categories: battery and fuel cell. In terms of type, the batteries currently used in new energy vehicles are all chemical batteries, usually lead-acid, lithium titanate, lithium cobalt oxide, lithium iron phosphate, nickel-cobalt, nickel-cobalt-aluminum five kinds of power batteries.

Among them, lithium iron phosphate batteries with high energy density and more stable performance and ternary lithium batteries are the two most widely circulated batteries in the power battery market, and they are also the most widely used main power sources in electric vehicles.

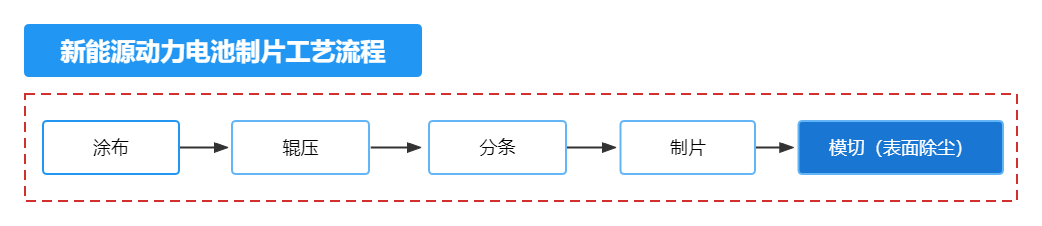

Power battery production process①

Production process · Die cutting: In the new energy power battery production process, USC dry ultrasonic dust removal is performed before and after die cutting, which can reach 98% dust removal rate. Effectively remove dust particles on the surface and ensure the quality of subsequent core assembly. Greatly reduce the failure rate and improve product yield.

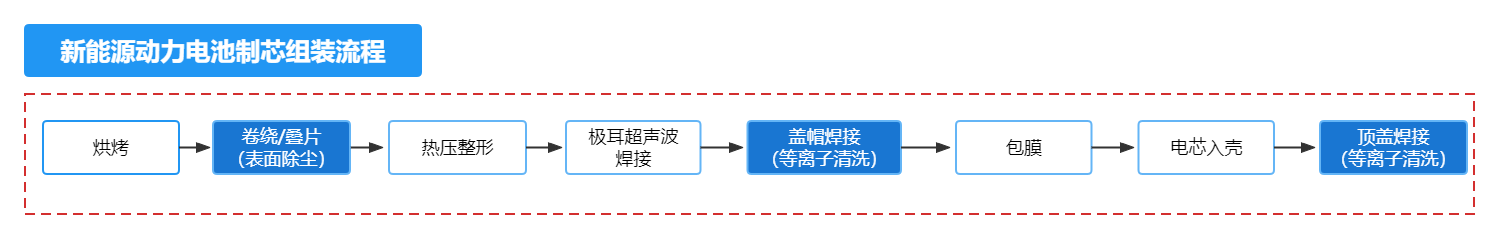

Power battery production process②

Cell assembly process · Winding/lamination: In the new energy power battery cell assembly process, USC dry ultrasonic dust removal and non-contact cleaning are performed before winding/lamination to separate the dust particles from the material surface. To achieve the purpose of dust removal, it is the most efficient, safe and clean dry dust removal method in the industry.

Power battery production process③

Cell assembly process · Cap/top box welding: If the surface of the cell has invisible dirt and dust, it will lead to false welding during welding, which will affect the reliability and durability of the cell. Therefore, plasma cleaning must be carried out before cap welding/top box welding, which can remove impurities such as organic matter or tiny particles on the surface, and prepare for welding in advance to reduce defective welding products.

Power battery production process④

Plasma treatment is used before gluing the cell, which can thoroughly clean the surface of the cell, roughen the surface of the cell, and improve the adhesion of subsequent gluing.

Why is the power battery highly concerned?

Industry analysts believe that the accelerated expansion of power battery companies is mainly based on the support of market demand. With the rise of the new energy vehicle market, the market demand for power batteries is also increasing day by day. "The huge market space and growth potential, as well as the industrial status of power batteries as the core of electric vehicles, have stimulated the outbreak of the automotive power battery track."