Lithium battery manufacturing process

-

Positive and negative active materials, conductors

-

Positive and negative electrode slurry preparation

-

Plasma cleaning①

-

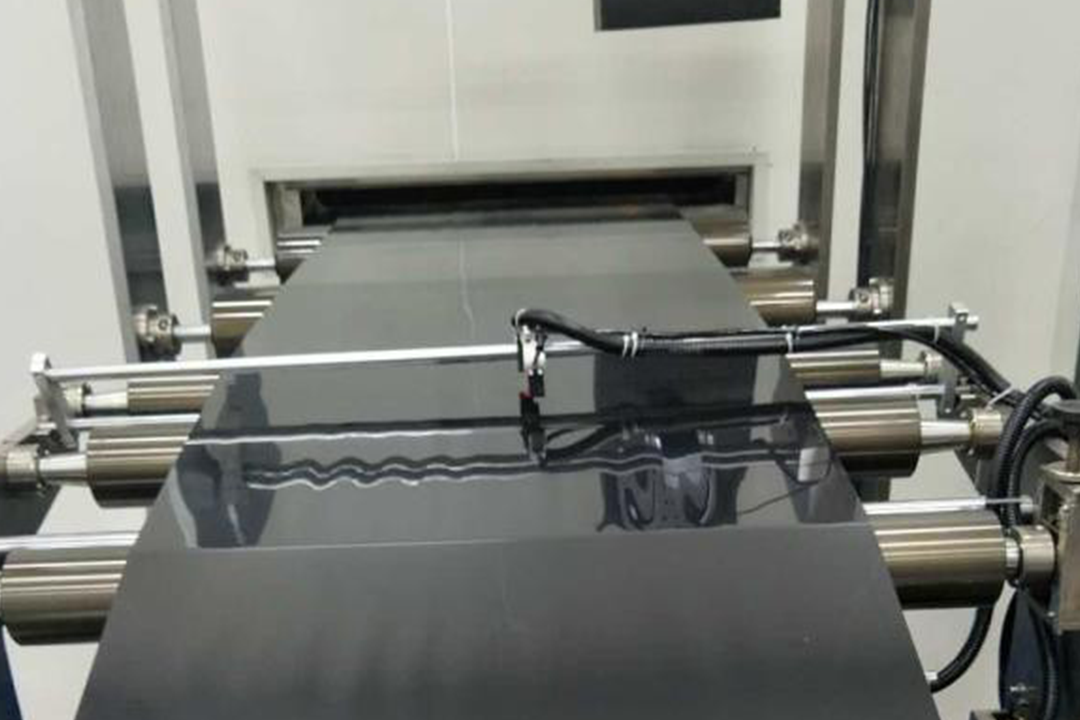

Positive and negative electrode coating

-

dry rolling

-

Pole piece, diaphragm slitting

-

winding/lamination

-

Plasma cleaning ②

-

Shell welding

-

sealing

-

inject electrolyte

-

form into

-

sorting

-

Plasma cleaning ③

-

assemble

Plasma cleaning

1 Plasma cleaning before pole piece coating

The positive and negative electrode sheets of lithium batteries are made by coating the positive and negative electrode materials on the metal film. The positive and negative electrode sheets need to be cleaned by plasma before coating. The single-sided density of positive electrode coating is ≈ 20-40 mg/cm2 (NCM power type), and the single-sided density of negative electrode coating is ≈ 10-15 mg/cm2. The material of the metal film is generally aluminum foil or copper foil. The previous cleaning method is wet ethanol solution cleaning, which is easy to cause damage to lithium batteries and other components. The use of plasma cleaning machine will not only cause no damage to the material and no residue, but also can remove the organic matter on the surface of the material, increase the wettability of the film surface, and improve the uniformity, thermal stability and safety of the coating.

2 Plasma cleaning before battery welding

If the tabs of the lithium battery cells are not flat, it will lead to false welding during the welding of the lithium battery, which has a great impact on the reliability and durability of the lithium battery connection. Therefore, it must be ensured that the surface of the tabs is free of invisible dirt and dust. Plasma cleaning is carried out before the welding of lithium batteries, which can remove impurities such as organic matter or tiny particles on the surface, and prepare for battery welding in advance, so as to reduce the defective products of welding.

3 Plasma cleaning during battery assembly

In the battery assembly process, in order to prevent the battery from short-circuiting and play the role of insulation, it is necessary to apply glue to the battery cell to improve the safety of use. Plasma treatment of insulating plates, end plates, PET films and other parts with a plasma cleaning machine before gluing can thoroughly clean the surface of the cell, roughen the surface of the cell, and improve the adhesion of subsequent gluing or gluing.

4 Summarize

Plasma cleaning technology can achieve complete cleaning effect in production, stable surface treatment, and effective cleaning of difficult parts. Therefore, increasing the plasma cleaning process can effectively improve the battery manufacturing process level.